But nevertheless, the efficiency of halogen bulbs is still very poor. Improved design increases the lamp life by a factor of 2 and higher and the luminous efficacy by 15 to 20% as opposed to incandescent lamps. The use of quartz glass envelopes allows halogen bulbs to operate at a high pressure, which not only retards the tungsten evaporation but also enables high temperature operation for higher color temperatures and greater efficiencies. Because of this recycling, the tungsten will not settle on the bulb wall to blacken it and the life of the filament is dramatically extended. The resulting compound decomposes when it hits the hot filament and is redeposited on the filament, while releasing halogen to again react with evaporated tungsten.

#Led projector retrofit free

At elevated bulb wall temperatures, the presence of this halogen in the bulb triggers a chemical reaction known as the halogen cycle whereby evaporated tungsten molecules combine with the free halogens to form a tungsten halide compound. The filament resides in an airtight glass envelope filled with halogen gas. Halogen bulbs produce light by heating the tungsten filament to the point of incandescence. In the past, halogen bulbs were the dominant choice of light source for vehicle front lighting applications. The removal of light that causes glare is performed by a light shield, which is inserted into the light path thereby creating the sharp beam cutoff. The projector headlight directs reflected light through a projection lens which produces a more focused beam of light with less scatter loss when compared to reflector headlights. Projector beam headlights produce a sharper, more focused beam of light thanks to the use of a hybrid optical system. Reflector headlights use a large parabolic reflector to yield the overall desired light distribution.

They throw light far enough to maximize visibility but would expose other drivers, bicyclists, and pedestrians to more discomfort, distraction, or glare than would be seen with lower beam headlights.Ĭonventional vehicle headlights can be divided into reflector and projector systems depending on the optical design. High beam (driving beam) headlights provide illumination beyond the range of the low beams.

#Led projector retrofit drivers

The low beam (passing beam) is designed to provide adequate forward and lateral illumination with a sharp, asymmetric cutoff preventing significant amounts of light from being directed into the eyes of drivers of preceding or oncoming vehicles. System design of conventional headlightsĪ vehicle headlight system is generally configured to switch between low and high beams based on driving conditions. A systems approach to lighting engineering allows the light source to last longer with effective heat sinking and tight load regulation while providing precisely controlled light distributions for optimal road visibility and glare control. Simply replacing the light source provides limited benefits.

LEDs, which are all the rage these days, are interdependent upon the thermal, optical, electrical and control system applied.

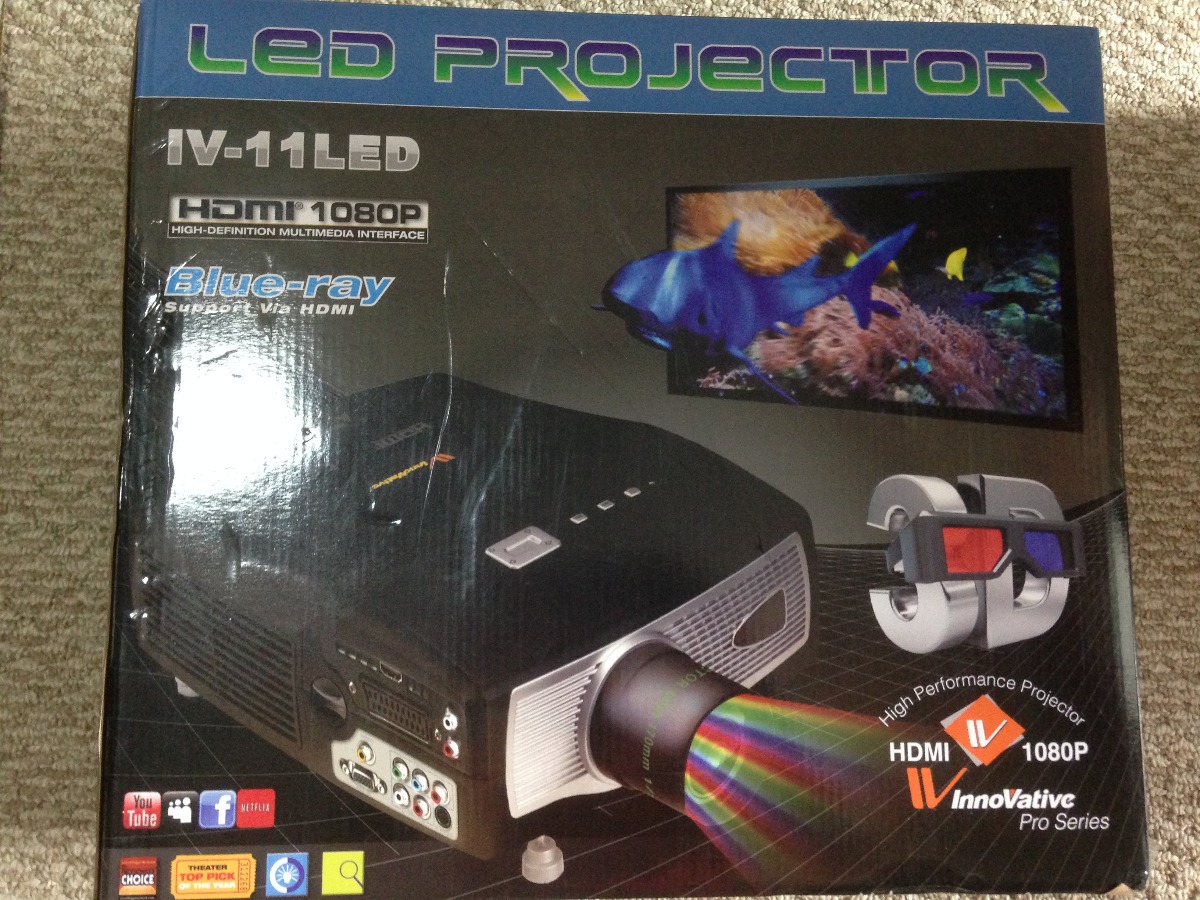

This product varies from the HID or LED conversion kit which provides only the light bulb for lamp retrofitting.Ī headlight retrofit kit is a single-beam or dual-beam module that is holistically designed and constructed to fulfil optical control, power regulation, and thermal management for the integrated light source.

#Led projector retrofit upgrade

A headlight retrofit kit is an integrated assembly of high beam or low beam light that is designed to upgrade the existing system from halogen to HID, LED, or laser without replacing the legacy headlight enclosure.

0 kommentar(er)

0 kommentar(er)